Design for Manufacturability

at Corbett Engineering

-

Our DFM process streamlines production, reducing the time it takes to bring your product to market.

-

By optimizing designs for efficient manufacturing, you'll see reduced production costs and minimized waste.

-

Our focus on tolerances and validation ensures that your product maintains consistent quality throughout its production lifecycle.

-

Identifying and addressing manufacturing challenges early mitigates the risk of costly design changes.

-

Benefit from the collective knowledge and experience of our engineers, designers, and manufacturing experts.

We understand that successful product development involves innovative design and ensuring that your designs can be efficiently and cost-effectively manufactured.

Our Design for Manufacturability (DFM) expertise empowers your projects to seamlessly transition from concept to production, saving you time, money, and headaches.

At Corbett Engineering, we take a holistic approach to DFM, considering every aspect of your product's design, materials, and production processes.

Our seasoned engineering team collaborates closely with your designers to optimize your product for the manufacturing phase.

Early Collaboration

We believe that DFM starts at the initial design stage. By involving our manufacturing experts early in the process, we can identify potential manufacturing challenges and design modifications that lead to a smoother production process.

Material Selection

Our team helps you choose the most suitable materials that meet your product's functional requirements and align with efficient manufacturing methods and cost considerations.

Simplified Complexity

Complex designs often lead to intricate manufacturing processes. Our engineers work to simplify designs where possible, reducing the need for specialized tooling and processes.

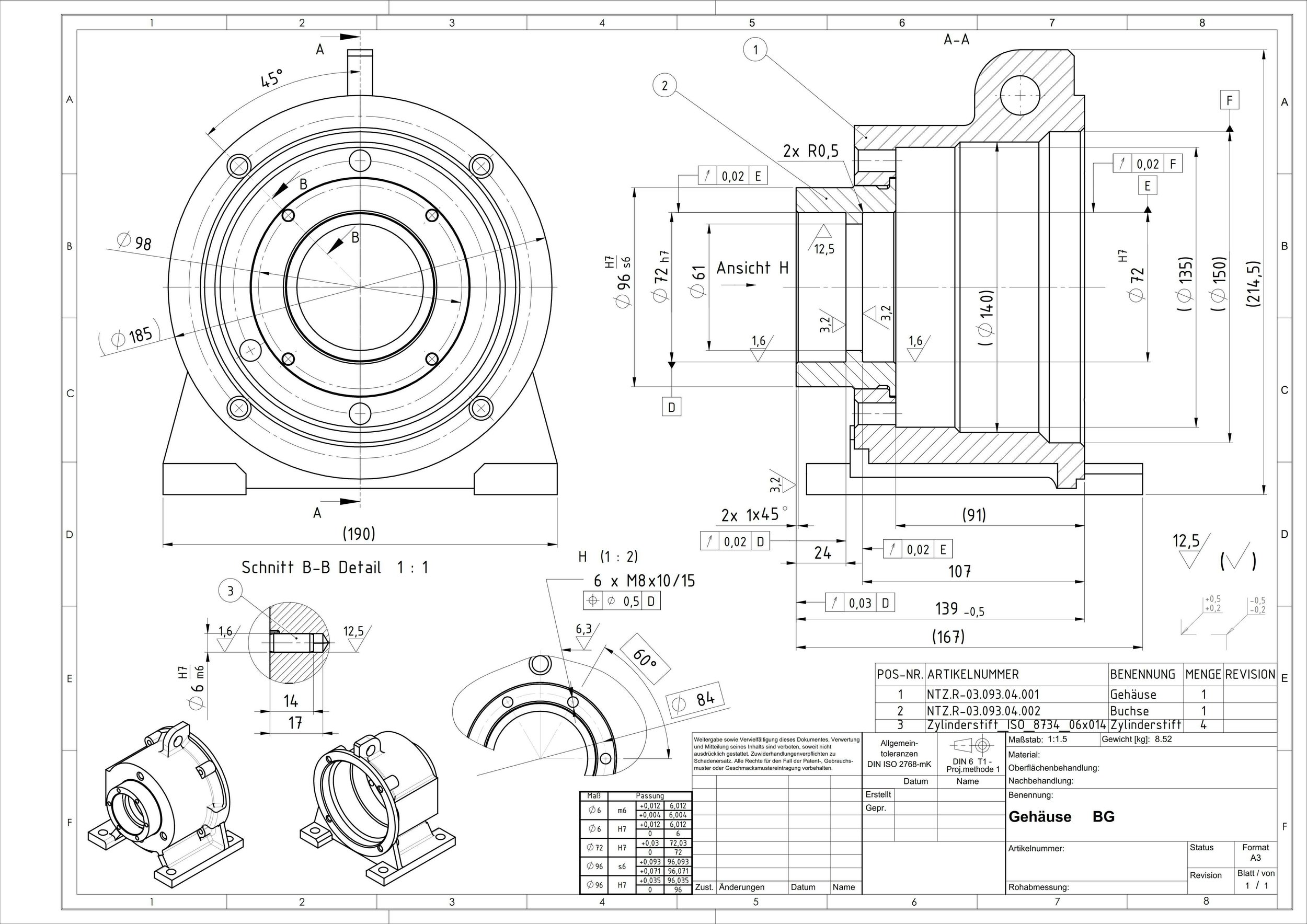

Tolerance Analysis

Proper tolerances are critical for ensuring parts fit together correctly during assembly. We conduct thorough tolerance analyses to prevent assembly issues and ensure consistent product quality.

Prototyping and Testing

Before full-scale production, we create prototypes to validate the design and manufacturing processes. This step helps catch any potential issues and fine-tune the design for optimal manufacturability.

Cost Optimization

Our DFM strategy includes evaluating the cost-effectiveness of different manufacturing methods, tooling options, and material choices. This way, you can make informed decisions that align with your budget goals.

Contact Our Engineering Team

Ready to make your designs a manufacturing success? Get in touch with Corbett Engineering's team of experts today.

We're excited to collaborate to bring your innovative ideas to life while ensuring efficient and cost-effective production. Let's work together to create products that stand out in the market.